Tube Bending Machines and Metalworking Equipment

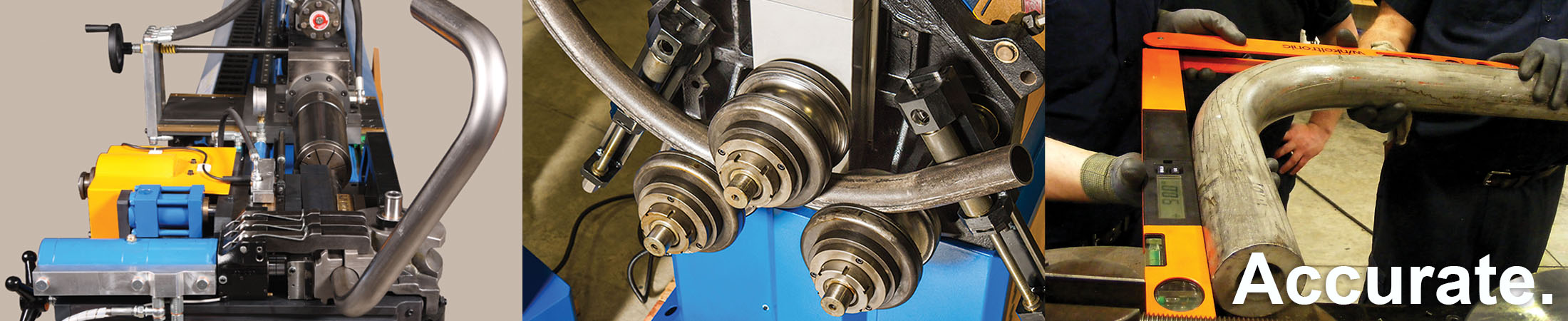

Ercolina Tube Bending Machines are Engineered for Efficiency

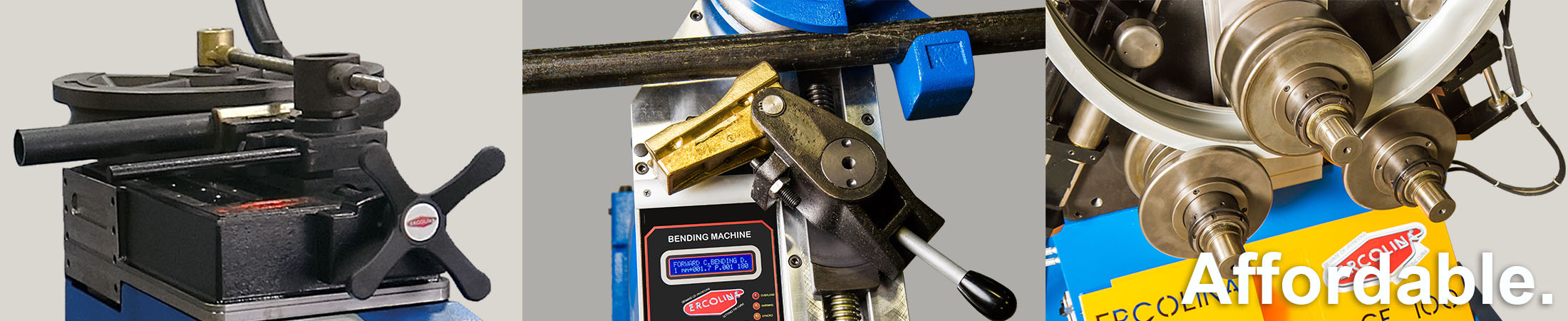

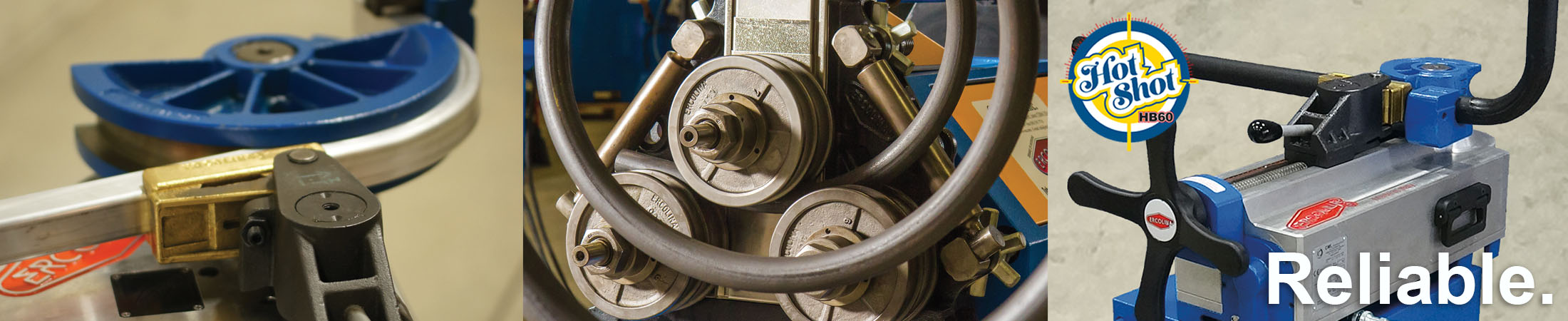

CML USA, Inc. is the North American supplier of Ercolina tube, pipe and profile bending and metalworking machinery. We are pleased to offer our customers the highest quality cost-effective tube bending machines and metalworking equipment to create consistent quality bends.

CML USA, Inc. inventories a wide variety of tube and pipe benders and tooling for round or square tube.

We also provide service parts for all Ercolina machine equipment and angle rolls/ring rolls (pyramid roller). For your convenience and support, our products are marketed through a network of local distributors and representatives. Our trained sales staff is backed by fifty years of experience in tube, pipe and profile bending applications. We consistently lead our field by providing quality metal fabricating equipment to commercial and professional metal fabricators in the United States, Canada, Mexico and South America. Contact us today for high-quality tube bending machinery and metalworking equipment for sale!

For the latest bending technology, SIGN UP to receive our newsletter Taking Care of Bending for tech tips, specials and more about our pipe bending machines!

Questions about the tube bending process?

Refer to our FAQ to discover more information about the bending process.